Designer Spotlight: Morgan O’Brien

INTRODUCTION

Morgan is from Rockville Centre, New York, a town on Long Island. He graduated in May 2021 from the University of Miami, FL, and started his career at Smith Gee Studio and life in Nashville soon after. Inspired by his father who was a general contractor when Morgan was young, he enjoyed tagging along to job sites and witnessing the process of construction. The designer joined us by sharing his experiences at architecture school and the technologies he had the opportunity to work with.

MOTIVATION

“Teammates. I’m always driven by the energy in the room. Sometimes all it takes is one person’s idea to spark inspiration. Once that great idea is introduced, everyone can run with it and build off it, and before you know it, you get sucked right back into the life of the project.”

Morgan noted that it is important, especially at the start of his career, to be “intentional about every design decision I make”. The professional architect is equipped with the understanding of the “implications of different design solutions and ultimately selects the one that best strengthens the essence of a project.”

Furthermore, it is invaluable to maintain the skills that we acquire; many designers, intend to sketch more and read more to stay at the peak of their design acumen and further it.

The project he is most proud of from school is designing a living facility for United Cerebral Palsy in Miami, FL. The project demonstrated “how much architecture and the built environment impacts lives, especially people that have very specific needs.” The facility emphasized the value of taking on a project that has meaning and passion from the designers, the owners, and those facilitating the everyday activities.

FABRICATION & MAKING: THE PROCESS

Most designers would agree that process is critical to being a successful designer and a helpful teammate to others. Our common journey through the various architecture programs shapes our “signature” process for collaboration and reaching a design decision.

Morgan shared that amongst sketching and various iterations, modeling and fabrication are so critical to the design process. “We can never fully understand what a design looks like until it is tangible and right there in front of us.” Analog methods are still valuable methods to test out design decisions, as many veteran professors and professionals would recommend: “if it doesn’t work in a scale model, then it probably won’t work in actuality”. How can we be extremely confident in our decisions if we only see them digitally? Ideally, a designer should have “quick, flexible study models” to make informed design decisions. Not only did Morgan strive to test models out in real life, but he also worked at the model shop and oversaw the facility as a student worker. The model shop at the University of Miami School of Architecture houses tools such as a CNC milling table, laser cutters, plastic and resin 3D printers, a virtual reality lab, and a robotic arm.

FABRICATION & MAKING: THE PROJECT

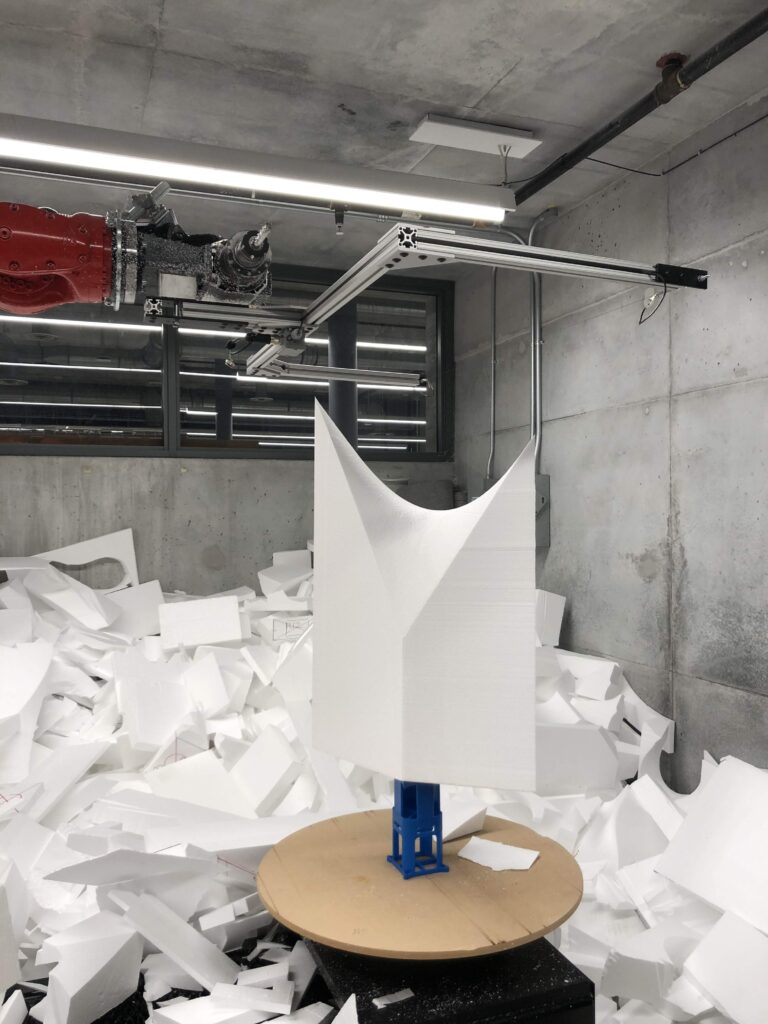

Morgan had the opportunity to be part of a design studio that studied the fabrication of a full-scale pavilion through the use of robotics. Other schools like my alma mater of the University of Tennessee have just embarked on that journey of experimentation with technology, but the University of Miami is already discovering and solving the vast frontier of automated design.

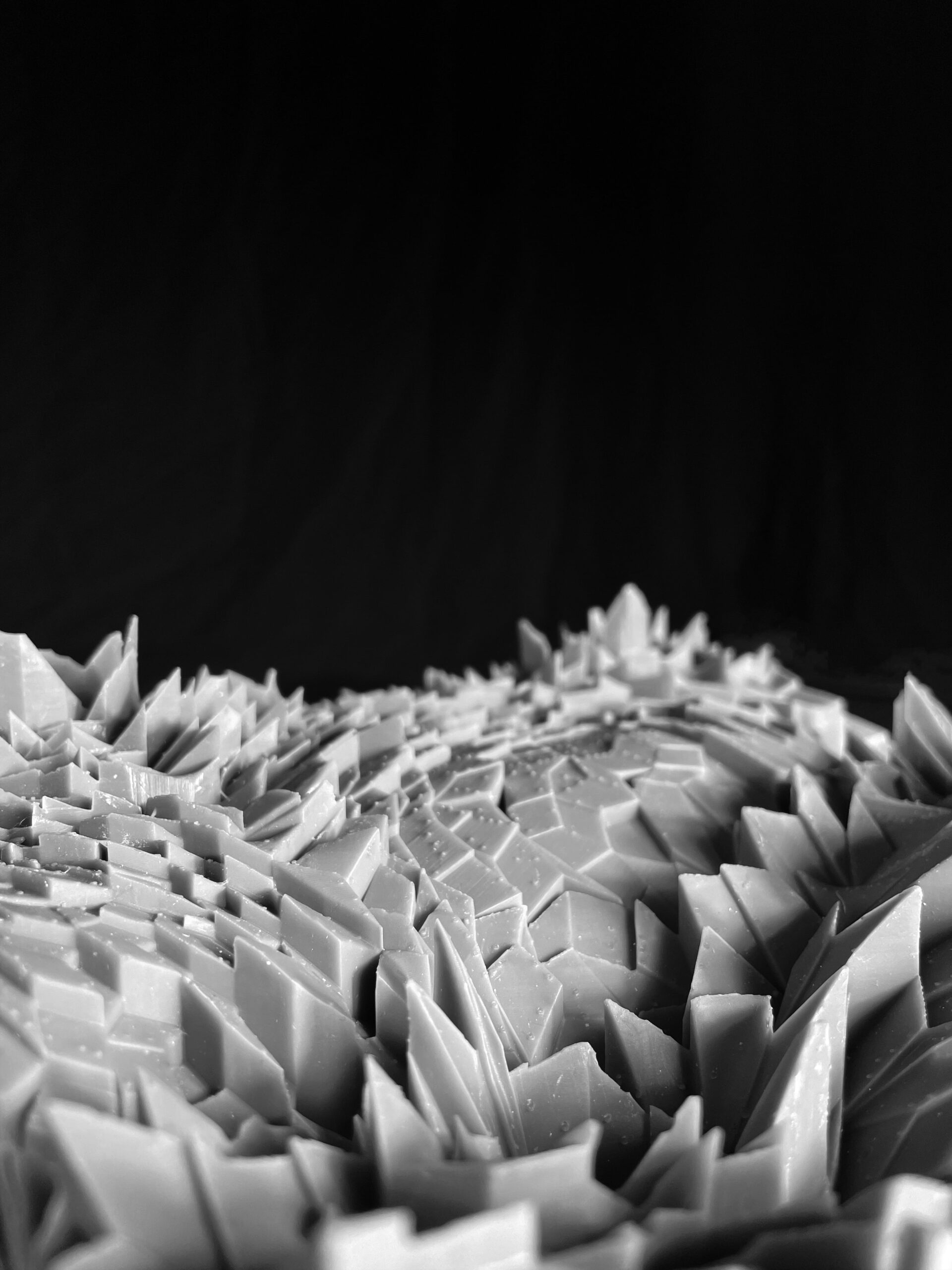

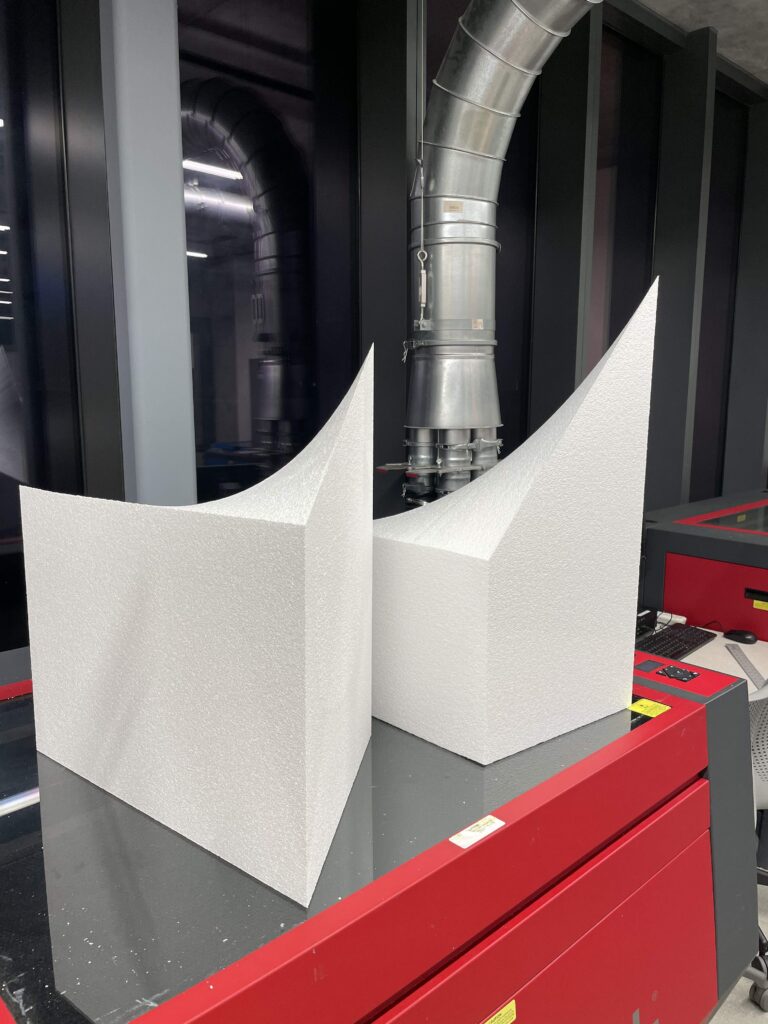

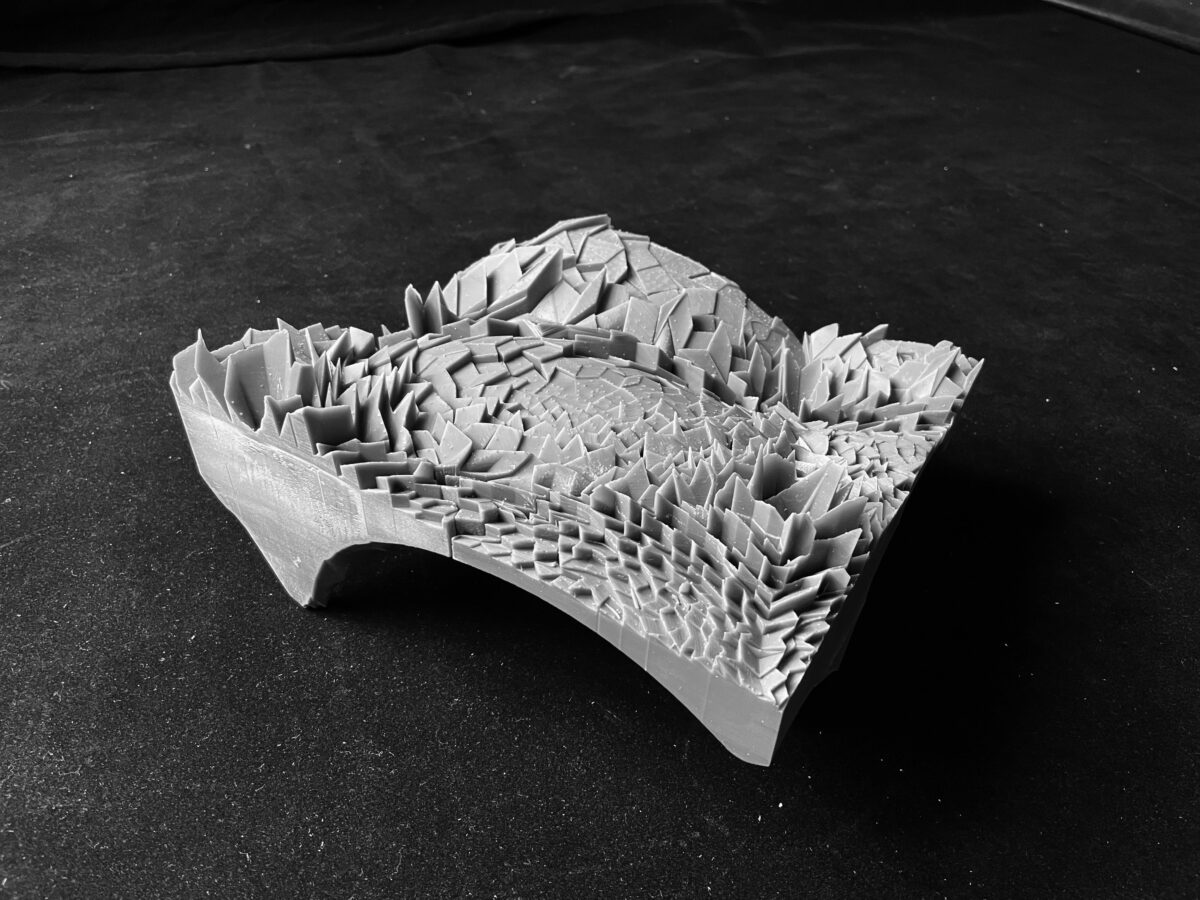

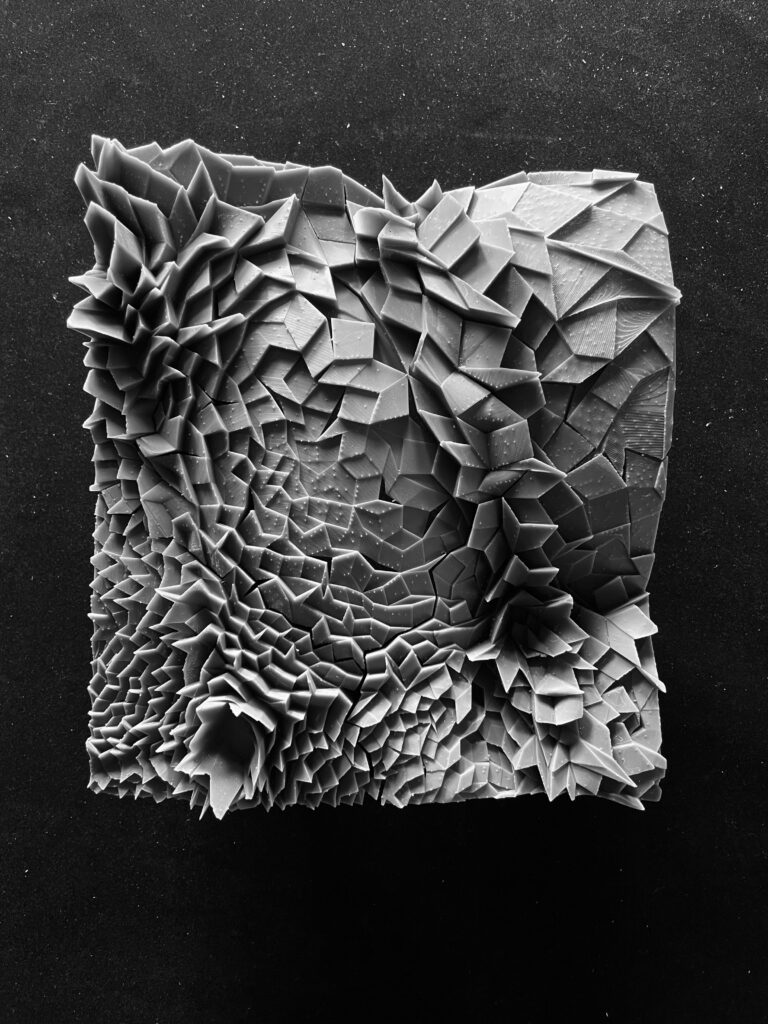

Not many of us have designed using a robotic arm, and for anyone, it can be quite the learning curve. This robot that Morgan and his peers were using includes a four-foot hot wire cutter attachment, so the students had to “understand ruled surfaces and how to create a variety of geometries from straight-line movements before we could begin designing.” Working with robotics in fabrication also means learning new programs such as Grasshopper to write scripts for the robot to carve the design. The students “had to think about the structural properties of the foam, the geometry of our structure, how to break down the overall pavilion into cuttable-sized pieces on the robot, and how everything would be assembled.”

The class of upperclassmen and graduate students split up into different teams, each focusing on different structural forms and opportunities with foam. The teams had to endure three learning curves: studying the path of a hot wire cutter and how it can rotate to design paraboloids; how to use the program Grasshopper to develop a script for the robot; and how to craft the script into movements on the robot.

Morgan’s team studied shell structures for their pavilion. They had to first design the shell’s global geometry and then divide that into parts small enough to be cut on the robot but large enough so the number of pieces to cut was manageable. After seeing the excess waste from previous test cuts on the robot, one of Morgan’s teammates suggested taking the unused half of each cut foam piece and placing it on top of the other instead of just throwing it away. As a result, the shell structure took a mirrored form that was very tall at its columns and thinner at its center, which is a visible expression of the structural properties of a shell.

The final review showcased the products of each teams’ research and demonstrated the structural frontier that automated technology can bring to us in this century.

FINAL THOUGHTS

It is difficult to stay afresh of novel technologies and techniques; however, learning about the unfamiliar process and results of using a robot to fabricate has energized me to be more curious and learn more about advancements in the built environment. We hope you also feel inspired and maybe we will see you at a future DRT about hyperbolic paraboloid architecture. Let’s throw in a robot for good measure.